|

|

O_MILL

Check out the benefits of O_Mill

AUTOPILOT to increase productivity and cement quality while reducing energy consumption in cement mills.

Handle startup and cement changes and avoids plugging.

Master varying clinker grindability.

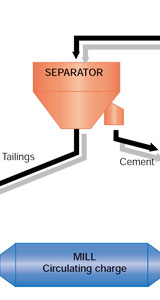

Based on various process measurements (e.g., electronic ear, flowrates, pressures, temperature) and on-line particle size distribution (PSD) analyzers or off-line quality analyzers (e.g. sieves, Blaine), O_Mill is designed to optimize cement quality, productivity, and energy consumption of a cement mill circuit by adjusting various process quantities such as the fresh flowrate, separator and fan speeds, and damper positions.

O_Mill is more than a piece of software!

Work through project phases:

-

-

- Evaluate the optimization potential

-

-

- Find fineness classes or off-line quality measurements that are statistically most relevant to the 28-day compressive strengths

-

-

- Using optimally designed experiments for production, study the effects of adjustable process quantities (flowrates, separator and fan speeds, pressures, grinding agent concentration, etc.) on the fineness classes, the off-line quality measurements, and productivity

-

-

- Design a customized optimization strategy that can first be tested ‘manually’ by the customer

-

-

- Implement and on-site commission O_Mill software

-

- Fine tune O_Mill software and implement remote monitoring

-

- Increase productivity and decrease energy consumption by more than 12%

-

- No need for maintenance contract or on-site expert since based on novel measurement-based optimization (MBO) technology

-

- Decrease the variability of the 28-day compressive strengths and grind only as fine as needed

-

- Handle mineral components of varying and unknown grindability

-

- Stabilize the material flows by avoiding segregation in the mineral-component bins and by controlling the circulating charge

-

- Manage mill startups and cement changes, avoid mill plugging

-

- In the absence of an on-line PSD analyzer, provide a nonlinear multivariate software sensor to estimate the Blaine and fineness from process measurements including automatic update from infrequent delayed laboratory measurements

-

- Fast on-site commissioning (a few days) thanks to a dynamic real-time simulator

- Connect easily to a customer PLC (ABB, Rockwell, Schneider-Electric, Siemens, Yokogawa, etc.)

O_Mill has been implemented in various cement mills.

Happy customers include: Holcim, Vicat.

”New productivity record with O_Mill.”

”We have been collaborating with Online for several years to improve the quality of our products and to increase the performance of our production plants. We have obtained significant improvements due to O_Mill, and other projects will be implemented in the near future.” To show the merits of O_Mill, an article was published in 2013 in the group journal in collaboration with Online.

Please contact us for more detailed information.

|

|

|